LS-609 is a laser particle size analyzer for the measurement of particle size distribution of dry samples within the size range 0.1 - 1000 microns Based on Laser Diffraction principles, the LS-609 makes use of a high performance He-Ne laser light source which is more stable and has lower warm-up times than systems using traditional lasers. Full automatic alignment of the laser and detector, the LS 609, through an intuitive software interface, allows both SOP driven or manual measurement protocol's.

Coupled with an automatic sample dispersion device utilizing variable control of pump sped stir speed along with variable ultrasound capability, allows making measurements simpler and more efficient for materials such as Minerals, Cement, metal powders.

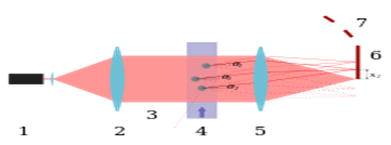

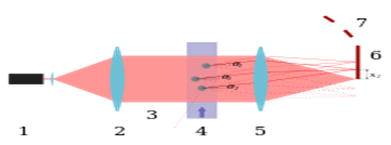

Laser diffraction analysis is based on the Mie Theory & Fraunhofer approximation, stating that the angle of scattered light by a particle is directly proportional to the particle size.

The angle of the laser beam and particle size have an inversely proportional relationship, where the laser beam angle increases as particle size decreases and vice versa.

A:large particle low angle scattering B: small particle wide angle scattering

Laser diffraction analysis is accomplished via passing particles suspended in a liquid medium contained in a measurement cell through a He-Ne laser. As the particle pass through the laser they "scatter light " at a certain angle. This angle is recorded on a detector which is then converted into particle size and size distribution based on Mie Theory. Resulting data is then displayed graphically through the appropriate operating software.

A lens is placed between the object being analyzed and the detector's focal point, causing only the surrounding laser diffraction to appear.

Optical bench LS-609

- Test Principle : Laser Diffraction (Mie & Fraunhoffer Scattering)

- Size Range : 0.1 - 1000 μ m

- Repeatability error : <1% (standard sample D50 deviation)

- Data Acquisition Rate : 1 kHz

- Test time : 1 - 2 minutes ( From measurement start to printed result)

- No. of Detectors : 49

- Light source: Helium - Neon laser, power: > 2.0 mW , wavelength: 632 nm

- Working environment : 5 - 35 ° C (temperature), 10-90% RH non condensing

- Output data : particle size distribution, average particle diameter, median diameter, specific surface area

- Bench Dimensions (L × W × H ): 838 x 265 x 295mm

- Package Dimensions : 938 x 365 x 395mm

- Power Supply : 220Vac +/-10%, 50Hz

- Dust protection : IP5x

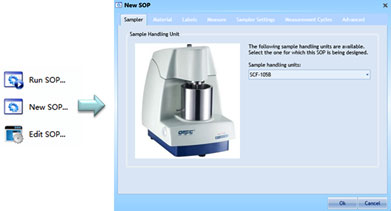

Wet Sample Dispersion Unit SCF-105B

- Easy to use fully automated sampler supporting manual or SOP driven measurement protocol's

- Dispersant volume : 500ml

- Sonication : Built-in upto 50W with variable continuous adjustment

- Auto Priming & Degassing

- Auto Draining & Cleaning

- Pump Speed with variable speed control up to 4000rpm using Swiss made brushless motor

- Assembled upon a rigid optical bench providing a robust & mechanical assembly for optical consistency across the optical path

- Modular design for easier service intervention where required

- Integrated cover design to enhance water and dust protection

- Optimised positioning of detector set with additional protection for dust and light contamination

- JDSU He-Ne laser 632nm wave length providing high resolution and excellent light stability thorugh good monchrome & coherency, low convergent angle and high energy concentration

- Central detector allowing for optimised laser alignment mechanisim

- 16 - bit sampling with 64 channels upto 1kHz

- Complies with EN61326 Part 1:2006 & EN61326 Part 2-3:2006 EMC standards

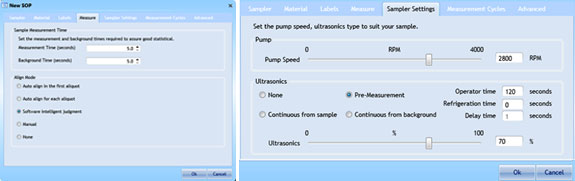

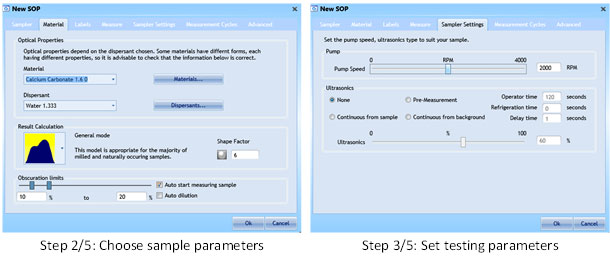

The LS-609 utilises a fully comprehensive and professional software package running on Windows 7 (32 bit) operating system and above. A simple, English Language, user friendly interface allows an SOP, or manual driven measurement process, where all aspects of the measurement and subsequent result calculation & reporting are controlled. A simple and concise software menu, driven by, simple and easy to understand "icons" is utilised for all major functions and processes such as cleaning, setting up SOP, database access or search.

Automated measurements

Fully automated measurements with full control over pump speed, sonication, measurement parameters such as duration & cleaning procedure as well as sample loading and alignment procedures.

SOP Driven Measurement Process

Whilst of course manual measurement is available many users prefer to use SOP'S ( standard operating procedures )/ These SOP's are designed in advance and take care of all key parameters in the various measurement steps. SOP driven measurements reduce greatly the error in a measurement by ensuring same parameters are used each time.

Database

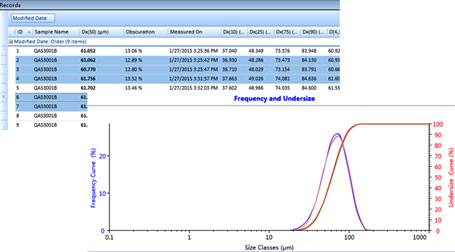

A comprehensive and expandable built-in database is provided for storing all measurement records and data allows fast retrieval and various reporting possibilities and result calculations including, result overlays and average record results.

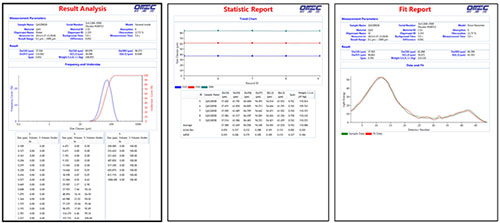

Result Reporting

Results can be presented in many formats such as trends, single page volume reports or even overlays. Additional report formats such as Sieve data can also be produced directly within the software. The user also has the possibility to make "custom" reports allowing complete freedom of what parameters are required for reporting.

Additional capability for exporting data in .pdf formats or to external software such as, Excel is also possible. Additional features allow the calculation of raw data using other algorithms such as "enhanced " or "single peak " mode.